The food processing sector requires to meet high safety standards and to use belts that will deliver optimal production efficiency.

Specific challenges

- belt standards and certification requirements, bacterial growth control, potential losses due to damaged products during production process

Beltal solutions

- Strict compliance with food standards (FDA, EU 10/2011 or EC 1935/2004)

- Belts impermeable to water, oils and other liquids

- Range of antimicrobial belts

- Belts for metal detectors

- Increased durability of FDA belts

- Cut-resistant belts preventing risk of bacterial contamination

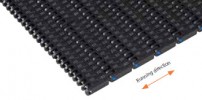

- Variety of configurations for plastic modular belts

- Specialty products and production processes reduce production line losses

Applications

- Meat processing: metal detectors, scales, cookers, cutting tables, boning, fryers, sealers

- Bakeries: moulders, ovens, fryers, coolers, freezers, cutters, transfer, convenience stores, slicers

- Fruits and vegetables: picking, washing, sorting, freezers, canning, slicers cookers, fryers, packaging

- Snacks: cutters, fryers, seasoning, bagging

- Dairies: pasteurizers, filling, string cheese equipment, metal detectors

- Confectionery: mixers, coolers, enrobers, packaging

- Bottling: washers, ovens, filling, pasteurizers, printing

Advantages and benefits of Beltal’s offer

- Great peace of mind thanks to Beltal’s extensive experience in the field

- Simplified ordering given the broad range of products and applications available

- Time and money savings since Beltal solutions make belts last longer

- Increased productivity by reducing losses due to contamination or damaged products