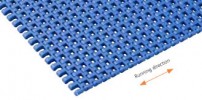

Many products of automated production lines require various types of conveyor belts.

Specific challenges

- In various industrial fields, protecting the integrity of the product during the production process is a key criterion.

- Transporting or transferring products over long distances, curves and inclines, or heavier loads may be issues for clients.

Beltal solutions

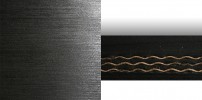

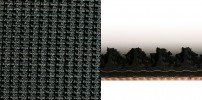

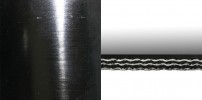

- Great cut and tear resistance for increased durability

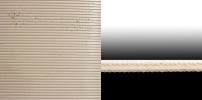

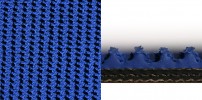

- Better adhesion of cover types to facilitate transport on ascending and descending conveyors

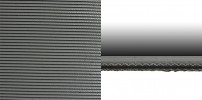

- Compliance with industry standards such as antistatic standards

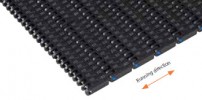

- Hidden mechanical fasteners to prevent damage to conveyed product

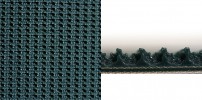

- Reinforced cleats able to carry heavier loads or softer cleats to avoid damaging the product

- Manufacturing of curved belts

Applications

- Recycling: stamping, waste processing, elevators, sandblasting, magnetic separators

- Packaging: line shafts, buildups, inclines, curves

- Textile: dryers, printers, transfer, cutters, drive shafts, winders

- Aggregates: screening, washers, slingshots, concrete conveying, hot-mix asphalt trailers

- Wood processing: sawmills, metal detectors, waste processing, sanders, coaters, tenoners

- Pulp, paper and paperboard: corrugators, stackers, transfer, folding, printing, packaging

- Pharmaceuticals: sorting, inspection, bulk shipping, packaging

- Parcel services: carriage of baggage, post offices, courier services

Advantages and benefits of Beltal’s offer

- Great peace of mind thanks to Beltal’s extensive experience in the field

- Simplified ordering given the broad range of products and applications available

- Time and money savings since Beltal solutions make belts last longer

- Increased productivity by reducing losses due to cuts on the belt or damaged products